Turnkey

Laser Tools

Turnkey laser tools

customized for your applications

Our turnkey laser tools are built on configurable platforms to bring you cost-savings. These platform-based laser tools can be delivered faster than completely custom-built machines, with better performance and often at a price that's comparable to off-the-shelf solutions.

Through our 360-Mastery Methodology, we work with you to determine which of

our configurable platforms below works best for your application.

Benefits of our platform-based tools

Configurable platform to fit your manufacturing needs

We have designed various platforms to fit different applications, form factors and sizes.

Each platform below includes:

-

Mechanical frame for stabilized motion

-

High precision motion controls

-

Industrial electrical sub-system

-

Class 1 laser safety enclosure (CDRH compliant)

-

Ergonomic user interface with touchscreen

-

Powerful turn-key software with upgrade options

-

Easy access for routine maintenance

-

Optional plans for TLS annual service

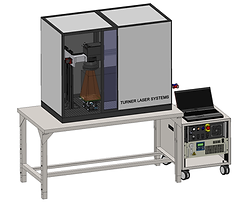

STANDARD PLATFORM

TLS Kanga

Our most popular platform is designed for product development, R&D, and low-volume production as a stand-alone unit but can be upgraded to fit as part of a high-volume automation tool. Processes parts as large as

500 x 400 mm size with micron-level repeatability. Comes with a Class 1 laser safety enclosure. Ideal for precision laser manufacturing.

Dimensions:

(WxDxH) 1.88 m x 1.19 m x 1.95 m

Weight:

1700 kg (approx)

Laser source:

Variety of ultrafast, nanosecond, fiber, UV and CO2 lasers

Beam delivery:

Variety of galvo-scanner and fixed-optic options available

Compatibility for automation upgrade:

Yes

Looking for higher throughput and precision?

Our Kanga platform is XL SCAN-compatible. (developed by our partners PI, ACS, and SCANLAB) .

COMPACT PLATFORM

TLS Wallaby

Similar to TLS Kanga, the Wallaby holds a smaller footprint. Processes parts as large as 300 x 200 mm size with micro level motion-repeatability. Comes with a Class 1 laser safety enclosure. Ideal for precision galvo-scanner based laser manufacturing with space restrictions.

Dimensions:

(WxDxH) 1.1 m x 1.1 m x 2.0 m

Weight:

500 kg (approx)

Laser source:

Variety of ultrafast, nanosecond, fiber, UV and CO2 lasers

Beam delivery:

Variety of galvo-scanner based options available

BENCHTOP PLATFORM

TLS Wombat

Our entry-level benchtop system is our most cost effective solution. If you're not looking for industrial manufacturing, this solution with lower precision capabilities and little versatility can be a great option for R&D in laboratories and feasibility testing.

LARGE FORM FACTOR PLATFORM

TLS Emu/Emu GX

A larger platform developed for processing much larger products and materials, with a variety of manual and automated loading options to optimize material handling in your manufacturing. Comes with a Class 1 laser safety enclosure. Ideal for large display and solar panel processing.

Dimensions:

(WxDxH) Various size options depending on material size.

Weight:

Depends on the size of material.

Laser source:

Variety of ultrafast, nanosecond, fiber, UV and CO2 lasers

Beam delivery:

Variety of galvo-scanner and fixed-optic options available. Also supports multi-head processing for higher throughput.

Compatibility for automation upgrade:

Yes

Upgrade options

All of our tools can be configured for additional upgrades:

-

Industrial high accuracy vision, for part alignment and inspection

-

Height sensor metrology, for automated focus adjustment (pre-map or on-the-fly)

-

2D line scanners, for 3D part measurement

-

Custom vacuum chucks and fixtures, for application-specific part handling

-

Integrated fume extractor, for debris management (or connect to facility exhaust)

-

Rotary stages for tube and curved object processing

-

Ionized air knives, for debris management

-

Integrated passive/active HEPA filtration, for medical clean environment operation

-

Automatic part loading, for advanced automation

-

Semiconductor cassette handling, for wafer loading

-

Active/passion vibration damping options

-

Temperature controlled process areas for ultra-high precision applications

In addition, we have many standard and custom automation options for automated high-volume manufacturing.

Feature | Kanga - Standard | Wallaby - Smaller Footprint | TLS Wombat - Benchtop |

|---|---|---|---|

Designed & Engineered for | Product development, R&D, and low-volume production | Precision galvo-scanner-based laser manufacturing with space restrictions | R&D & feasibility testing |

Overview | Engineered for versatility, precision, with premium stages, granite, and automation compatibility. | Compared to Kanga, it has galvo delivery only, with no granite and less versatility. | Our entry-level solution with no stages, and limited laser/lens versatility. |

Class 1 enclosure | ✓ | ✓ | ✓ |

Multi-Laser or Multi- Head compatible | ✓ | ||

Galvo compatible | ✓ | ✓ | ✓ |

Fixed optic compatible | ✓ | ||

High precision linear stages | ✓ | ✓ | |

Granite base | ✓ | ||

High precision vision | ✓ | ✓ | Basic vision |

High precision height sensor / autofocus | ✓ | ✓ | |

Compatible with automation | ✓ | Limited options |